We are sound.

And we believe

you are, too.

RTK is a mid-range brand in rolling & friction bearings, as well as bearing housing units.

To us, mid-range means that RTK is a great choice for many applications, reliable and delivers in line with all reasonable demands, in regards to integrity, sustainability and general quality. Hence, RTK is a must-go-see for many demanding industrial manufacturers.

By the way, we offer two value propositions: RTK and RTK Plus. They both offer high technological levels, but RTK Plus gives our customers the opportunity to tailor all documentation and specification to the exact extent necessary in the certification and specification work of their organizations and processes, on a very detailed degree.

Core range

- Standard quality

- Standard item inspection by AxInter China

- Factories audited and approved by AxInter China

- Standard certificates

Advanced range

- Extended quality

- Extended item inspection by AxInter China

- Factories audited and approved by AxInter China

- Better material and/or higher ranked factory

- Tailored documentation

- Tailored specifications

- Advanced certificates

Nordic innovation demands reliability.

These are our product categories.

RTK offers a full range and a wide assortment.

Rolling bearings*

Deep groove ball bearings, miniature ball bearings, angular contact ball bearings, self-aligning ball bearings, thrust ball bearings, cylindrical roller bearings, spherical roller bearings, full complement cylindrical bearings, tapered roller bearings. Single row, double row, multi-row, sealed or shielded vs. open. All from very small, to very large sizes.

Typical bearing materials: through-hardened bearing steel, case-hardened bearing steel, stainless bearing steels for corrosion resistance, ceramic rolling elements, full ceramic bearings. cages stamped steel, brass, polyamide/PA66 or other polymers, PEEK and other high-performance plastics.

Others: stainless or coated cages and rings, e.g. black oxide, phosphate, DLC, chrome coatings. Special steels for high temperature applications. Standard and special requested greases are available.

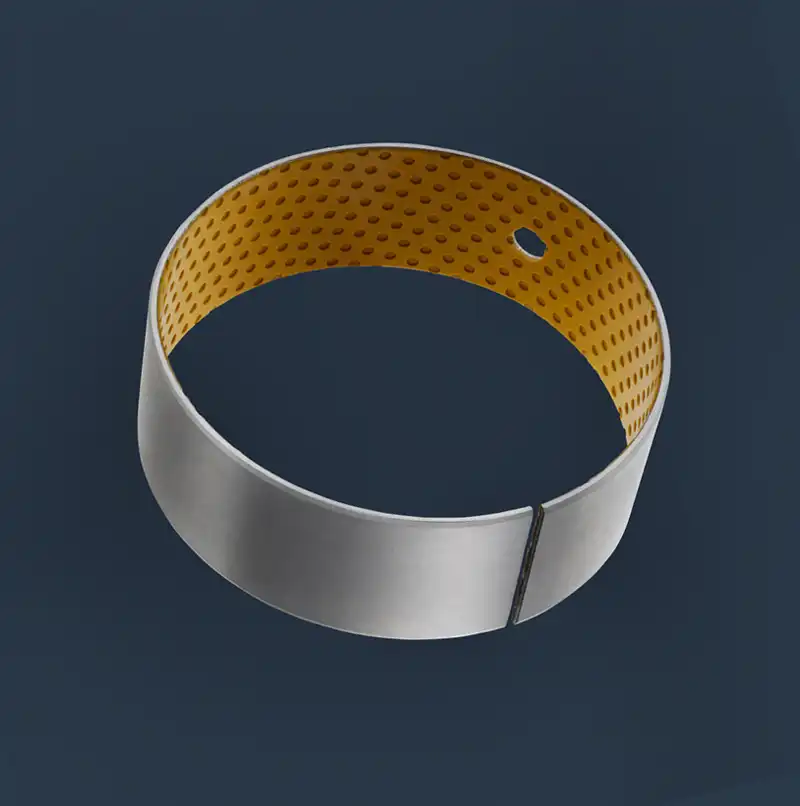

Friction bearings*

Slide bearings, spherical plain bearings and rod ends are available in sizes ranging from compact units to very large dimensions, suitable for everything from general industrial use to heavy‑duty and demanding applications.

The range includes designs for radial, axial and combined loads, with options for standard, misalignment‑compensating and heavy‑load executions.

Multiple material combinations – including bronze, steel, stainless steel, metal‑polymer, engineered plastics and fiber‑reinforced composites – are offered as both re‑lubricatable and maintenance‑free solutions to ensure optimal performance, long service life and flexibility in every application. Different designs and sliding material combinations are tailored to match load, speed, temperature and environmental conditions, using grease or oil lubrication, solid lubricants or low‑friction liners as required.

Options include seals, stainless steel or coated surfaces for enhanced corrosion resistance, as well as custom dimensions and special materials for challenging environments.

Bearing housings*

Pillow block, flanged units 2-bolt flange, 3-bolt flange, 4-bolt flange, take-up units, standard UC-type insert ball bearings, UK-type with adapter sleeve locking, eccentric locking collar, concentric locking (clamping ring) for better balance. Standard deep groove insert or wide inner ring versions.

Typical housing materials: Cast iron (grey or ductile), pressed steel / sheet steel, stainless steel housings, thermoplastic housings (plastic housings), special housings, cast stainless, coated cast iron (e.g. epoxy), or nickel-plated for high corrosion resistance.

Insert bearing materials, rings & balls, through- hardened bearing steel (e.g. 100Cr6/52100-type), stainless (e.g. AISI 440C types) for corrosion resistance, black oxide or other coatings, cages, steel, polyamide, stainless, seals NBR rubber, FKM/Viton or others for higher temperature or chemical resistance. Standard, and special requested greases are available, sealed or triple-lip sealed for harsher environments.

* Available in both RTK & RTK+

Our commitment to quality demands hands-on, and minds-on, work.

RTK’s core is quality thinking. And we believe that people who feel better, do better.

Therefore, through Axel Johnson International’s quality and sustainability center AxInter China in Ningbo, just south of Shanghai, we continuously provide feedback and training to our suppliers, to help them provide good living and working conditions. This, in turn, makes it possible to run successful programs to improve quality, safety, and sustainability.

AxInter China’s services are, in short:

Sourcing Services: Identifying new products and suppliers, and managing and developing the supply chain.

Procurement Services: Purchasing and delivering products.

Quality Services: Conducting supplier audits, pre-delivery inspections, product testing, and managing specifications.

Sustainability Services: Performing supplier code of conduct audits outside Europe and providing supplier training to support compliance and continuous improvement.

Axel Johnson International have run this facility since 2018. Around 20 people work, every day, to keep our promises to our customers. And to the world.